Anti-Dust Mite and Allergen Proof Pillowcase Nanocotton® Certified organic cotton with nanofiber membrane

Code: NS.11.019 NS.11.103 NS.11.018 NS.11.017 Choose variant

Related products

Product detailed description

Why is Nanocotton® Anti-dust Mite Bed-linen So Unique?

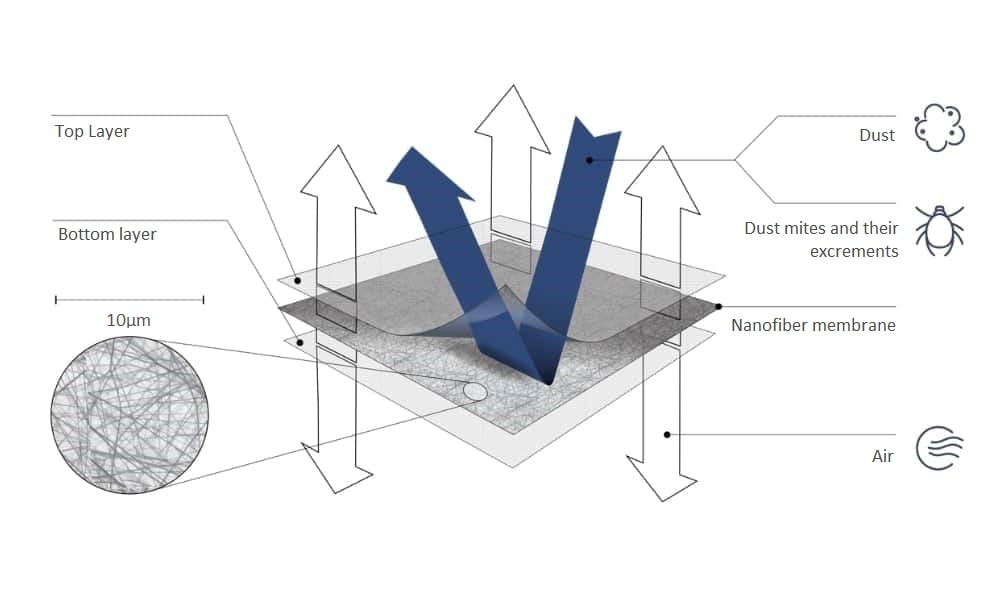

It is made with a three-layer laminate of high quality organic cotton and nanofiber layer. The functional layer is a nanofiber membrane that provides allergy sufferers with full protection from dust mites and allergens. The next layer is cotton satin, which is made from the finest 100% cotton yarns. Cotton satin has a dense and firm texture with a fine glossy finish, it absorbs moisture excellently and is breathable, this is due to the natural raw material from which it is made. The vibrant colours are stable even after many washing cycles. Nanocotton® is suitable for all types of bedding, including feather bedding.

Why Do We Use Organic Cotton and What Makes It Different?

Is It Important to protect yourself from dust mites?

We spend 8 hours a day (children up to 12) in our bed with dust mites, we provide them with food them as they feed on skin debris and we breathe their allergens from millimetres away. There can be up to two million mites in one mattress, and more in pillows and duvets. Dust mites and excrements (allergens) are the cause of allergies, asthma and respiratory diseases. The ideal conditions for their life are 22 to 26 °C, lack of light and humidity of 60 to 80%.

Mattresses, duvets and pillows are clearly the most abundant source of dust mites. Because of this, allergy sufferers or more sensitive people (adults, but especially children) cannot rest at night. This reflects on their mood, but also on their reduced attention during the day.

Maintenance

We recommend washing Nanocotton sheets before first use and without fabric softener at 40°C for longer durability in a chlorine- and phosphorus-free washing gel or powder (you can wash at 60°C if necessary). For example, the following products are also suitable for washing nanofiber materials. We do not recommend tumble drying, even at low temperatures.

How Does Nanofiber Work?

The nanofiber layer inside the Nanocotton® anti-dust mite pillowcase has holes between the individual fibers that are only 80 nm in size. The size of a dust mite is around 420,000 nm, its allergen is 1,000 nm in size, bacteria 100 - 10,000 nm, virus around 100 nm and scabies 300,000 nm. Thus, they have no chance to pass through the fabric. They cannot collect in the bed, multiply and cause allergic reactions and respiratory diseases. Both children and adults feel relief from allergies immediately after the first night, which results in a significant energy boost and improved attention span.

The Effectiveness of the Nanofiber Layer Has Been Tested in The Following Institutes:

- Textile Testing Institute in Brno (penetration of microorganisms).

- Technical University of Liberec (penetration of dust particles of 1micrometer size)

- State Institute of Health in Prague (skin tolerance and possible allergic reactions)

Testing Results:

- Effective capture of microorganisms was verified ≥ 99.0%.

- Effective capture of dust particles was verified ≥ 99.0%.

- No negative reactions in contact with human skin have been demonstrated

What Is the Material Made of?

- It is a three-layer laminate, which is composed of:

- 100% organic cotton fabric

- Nanofiber membrane 100% Polyamide 6

- Fabric 100% polyester

Material Certification

The used nanoSPACE fabric is certified by the OEKO-TEX® STANDARD 100.

We recommend treating the ceiling in the bedroom, and possibly other rooms, with FN NANO® self-cleaning coating, which will eliminate allergens, bacteria and viruses from the air. An equally effective solution is a portable ozone generator, which effectively cleans the air of mould, allergens, viruses (including COVID-19), bacteria and odours...

Related Articles

Additional parameters

| Category: | Nanocotton® – Next Gen Bedding For Allergic People |

|---|---|

| EAN: | 8594183610788 |

| Material: | Organic Cotton |

| Pillow size: | 45 x 60 cm, 50 x 60 cm, 50 x 70 cm, 70 x 90 cm |

List of ratings

The Czech company nanoSPACE has been operating on the market since 2012 and focuses primarily on products where nanofiber textiles are used. In 2012, it became the first manufacturer to use a nanofibrous membrane in barrier covers for allergy sufferers. Since then, it has expanded its portfolio to include nano duvets and nano pillows, which are especially suitable for people with dust allergies.

In 2016, it was the first in the world to present functional bed linen that can fully replace barrier coatings. This product line, which bears the name Nanocotton®, was able to combine the functionality of the material with organic cotton and is suitable not only for allergy sufferers, but also for atopic patients.

During the coronavirus epidemic in 2020, nanoSPACE used its long-term knowledge in the field of nanofiber materials and started the production of anti-virus neck gaiters and protective masks made of nanofiber. From 2021, it also produces designer washable nano masks.

In 2021, the nanoSPACE company founded the subsidiary nanoSPACE Technology, which is dedicated to development, research and innovation in the field of nanofiber textiles.