SPURTEX® Unisanol Mask and Respirator Disinfectant

Code: 1928

Related products

Product detailed description

Why use Spurtex disinfectant on nanofiber masks, respirators and antivirus gaiters? The ethanol-based disinfectant is approved for sterilization directly by the nanofiber membrane manufacturer. Unfortunately, most of the disinfectants available on the market contain other additives that could foul the nanofiber membrane and make it unusable. Spurtex disinfectant is tested directly on Spurtex nano drapes and Spurtex nano respirators.

The Disinfectant Does Not Smell when Applied, but Is Effective and Gentle on the Membrane

The disinfectant is ethanol-based, so you can't expect it to smell nice. Unfortunately, it is not possible to develop a disinfectant for nanofiber respirators that smells nice. Fragrance essences can foul the nanofiber membrane. :-)

Masks and respirators are most commonly used as filtering material to protect us against viruses (Covid, etc.), bacteria, particulate matter (smog, ash, etc.). SPURTEX® series filter materials are primarily designed for single use. To increase the viability of the material (reusability) and to ensure maximum protection, these materials can be disinfected.

How to Use SPURTEX® Unisanol Disinfectant on Nanofiber Drapes and Respirators?

It is advisable to disinfect the material after each use of the mask/respirator. It is recommended to wash your hands thoroughly before and immediately after disinfection (antibacterial gel).

Shake the disinfectant bottle thoroughly before use. Spray the mask/respirator with disinfectant on the outside and the inside. When spraying the material, keep a distance of approx. 15 cm, apply the spray in an even (no maps on the material) amount over the entire surface (ears). It is sufficient to spray 2 to 3 times on each side of the material. Do not apply spray on respirator/mask while it is worn on the face.

After thoroughly disinfecting the material, allow the face shield / respirator to air dry (24 hours is recommended, to reduce the risk of breathing in residual alcohol vapours). It is not recommended to use dryers to dry the material as mechanical damage to the filter layer may occur. In addition, increased thermal stress on the material using a microwave oven or hair dryer is not recommended.

The mask/respirator can be reused after thorough drying. It is best to allow the material to dry and air out overnight to prevent inhalation of residual disinfectant. This process can be repeated up to 5 times (depending on the wear of the mask/respirator) without affecting the filtering functionality of the material.

Does Disinfection Reduce the Effectiveness of the Nanofiber Material?

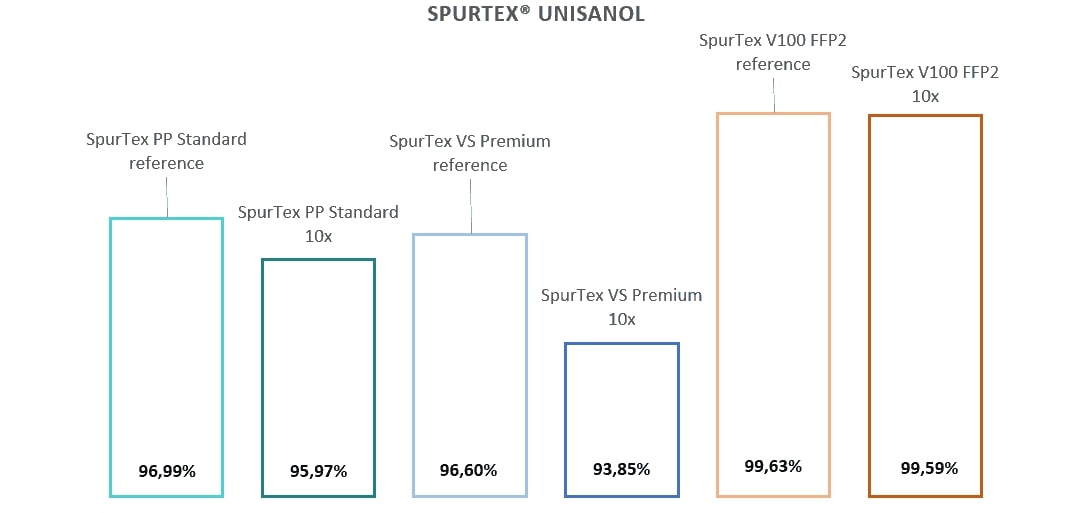

SPURTEX® Unisanol disinfection does not significantly affect the functionality of the filter material, but it does affect the aesthetics (appearance). As the number of applications of the disinfectant on the material increases, the elasticity is lost. This is most pronounced in SpurTex® VS Premium masks, where the material appears shrunken. In our testing of the disinfectant on nanofiber masks after 10 applications, there is a decrease in filtration efficiency of approx. 0.05% for PP Standard nano masks and approx. 1% and 3% for VS Premium nano masks. The values are measured in a clean environment, in the case of more dusty environments the values may vary.

SpurTex® VS Premium viscose sample before and after five disinfection applications. Manifestation of loss of material elasticity, shrunken appearance.

Something to watch out for is also the dispersion of the material's print (not applicable to the antiviral gaiter, where the disinfection does not affect the print), which may appear at the earliest after three applications of SPURTEX® Unisanol disinfection, especially for the SpurTex® V100 FFP2 respirator.

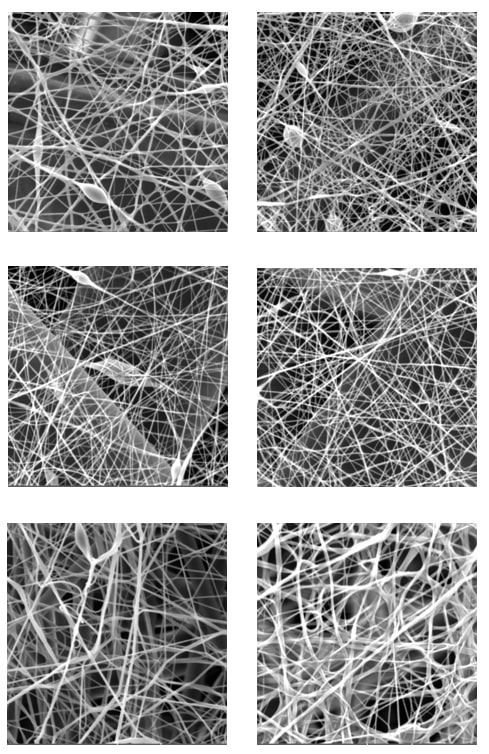

The effect of disinfection wear on the filter material can be characterised by a change in aesthetic appearance, such an assessment is only superficial. Other measurements such as the breathability of the material (pressure resistance) and the state of damage of the nano membrane (SEM - scanning electron microscopy) were performed.

The Results of the Pressure Resistance

Pressure resistance (breathability of the material) is one of the basic characteristics of respirators/muffs. It is a parameter that tells us how easy it will be to breathe in the respirator. The following table shows the values of the percentage change in breathability of the filter material for 5 and 10 applications of SPURTEX® Unisanol disinfection. The results show that SPURTEX® Unisanol disinfection (at 5 applications) results in changes in material breathability of up to 9%.

|

|

Disinfectant |

|

|

SPURTEX® Unisanol |

||

|

Number of disinfection cycles |

5x |

10x |

|

SpurTex® VS Premium |

3,9 % |

15,2 % |

|

SpurTex® PP Standard |

4,6 % |

5,1 % |

|

SpurTex® V100 FFP2 |

8,6 % |

8,7 % |

|

Table showing the absolute percentage change in material permeability when SPURTEX® Unisanol disinfectant is applied at 5x, 10x.

|

||

Salt (NaCl) particle capture

The percentages indicate the filtration efficiency of the material, or the amount of particles trapped that do not pass through the material. The value of the reference that has not been disinfected and the value after 10 cycles of disinfection of the material are always given.

Scanning Electron Microscopy (SEM) Observations

| REFERENCE | SPURTEX® Unisanol | |

| SpurTex® VS Premium |  |

|

| SpurTex® V100 FFP2 | ||

| SpurTex® PP Standard | ||

| SEM at 5000x magnification for SpurTex® V100 FFP2, SpurTex® PP Standard, SpurTex® VS Premium respirator with SPURTEX® Unisanol disinfectant application, reference without disinfectant application. | ||

Benefits of Using SPURTEX® Unisanol Mask and Respirator Disinfectant on Nanofiber Products

The advantage of disinfecting the material is a higher intensity of protection for the consumer, against viruses, bacteria. Other advantages include higher usability of the material as such. The mask/respirator itself is intended for single use. When reused, the amount of plastic waste generated is eliminated. With SpurTex® VS Premium viscose, which is biodegradable, this is not such a big problem. However, this is not the case for the polypropylene PP materials SpurTex® PP Standard and SpurTex® V100 FFP2. Disinfection does not significantly affect the functionality of the filter layer (PVDF nanomembrane). The repeated use of one product reduces the financial costs required to purchase disposable products.

The disadvantages of repeated and frequent disinfection of respirators/muffs are loss of aesthetic appearance, loss of elasticity, slight dissolution of some types of printing. The disinfection cycle is time consuming for the application as it requires time for the material to fully dry and air out.

It is up to the consumer to decide which route to take.

Additional parameters

| Category: | Disinfectants |

|---|---|

| EAN: | 8594053451824 |

| Intended for: | Face mask and respirators |

| The item has been sold out… | |

I recommend the product, it allows the reuse of masks and respirator

Total. satisfaction

I don't see "inside" how the disinfection works, so I can hardly rate it. And it has no other purpose.

The nanotechnology company Spur from Zlín has been operating on the market since 1992, when it mainly dealt with the production of plastic products. After several years of intensive research in the field of nanotechnology, she presented the results to the public at the NANOTECH 2012 fair in Japan.

Since 2018, SPUR has continued research and testing within the Center for Polymer Systems at UTB, where it continues to develop and produce its own nanofibers. Serial production of the nanomaterial began in March 2020 with significant advisory and consulting support from the Ministry of Industry and Trade and CzechInvest.

The production program of protective equipment includes, in addition to certified respirators and nanofiber masks produced on machines, also special sewn NANO masks SpurTex for adults and children, which are 97% BIO-based, i.e. made of natural material - viscose. They are breathable, ensure a comfortable and at the same time tight fit to the face and provide maximum protection against viruses and bacteria.

We also presented filter materials with SpurTex nanostructures. Spur is a member of the Nanotechnology Industry Association of the Czech Republic and part of the popularization project Czechia is nano.

About nano respirators

SPUR a.s. is a company based in Zlín, which in 2012 developed its own line for the production of nanofibers SPIN Line and since then has been developing filtration nanomaterials of the Spurtex series. In February 2020, it brought to the market a new type of nanomembrane, Spurtex VS, which meets the standards for the production of medical masks functional for the capture of coronavirus.

Spurtex VS material captures 70 to 95% of particles and does so at low pressure resistance (45 to 85 hPa), which makes end products highly breathable. SPUR respirators and masks meet FFP2 capturing requirements.

SPUR masks

SPUR nanofiber masks are disposable and serve as professional protection against viruses, bacteria, smog and allergens.

The material SpurTex® VS L2 V1, from which the nano mask is made, fully complies with the material requirements of the European standard EN 149:2001+A1:2009 for filtering half-masks against particles and meets the quality class FFP2. However, thanks to the unique properties of the nanofiber filter layer, the SpurTex® VS L2 V1 material also exhibits excellent capture efficiency in the ultrafine particle range (10-400 nm) and is therefore ideal for the capture of a wide variety of bacteria and viruses (the SARS-CoV-2 virus has a reported realistic size of 80-150 nm).

SPUR offers masks for children and masks for adults.

SPUR respirators

SPUR respirators have a proven capture of 98.5% and meet quality class FFP2 and FFP3 (the latter requires capture of at least 94%). They are cheap, light and very breathable. Respirators are valveless and suitable for professional and home use.

Filters for masks SPUR

SPUR also produces disposable filters for cotton masks from the same material.